- Fast InstallationPipe with rebated/ogee joint can be easily installed without sophisticated jacking equipment. This kind of rigid joint method is conveniently installed in properly layered hard and flat ground condition.

- FlexibilityPipes with spigot & socket with rubber ring joint can offer flexibility in certain degree of turning radius while maintaining the robustness of the pipe. A certain level of deflection due to soil settlement can be accomodated by this kind of flexible joint method.

- DurabilityPipes with protective layer such as high alumina cement lining or sacrificial concrete lining provide resistance to continuous exposure to hydrogen sulphide and wide variety of chemical corrosion attacks.

- Quality AssurancePrecast pipes are manufactured under controlled factory environment with stringent ISO 9001:2008 quality management system.

- Superior StrengthPipes manufactured with centrifugally spun process can achieve an equivalent high compaction due to coupling effect of vibration and centrifugal force.

contact info

if you want contact me:

Email: rebecca@sdcicq.com

Skype: rebecca.liunn

Tel:86 15318906257

2015年4月29日星期三

pipe ADVANTAGES made by CICQ concrete pipe

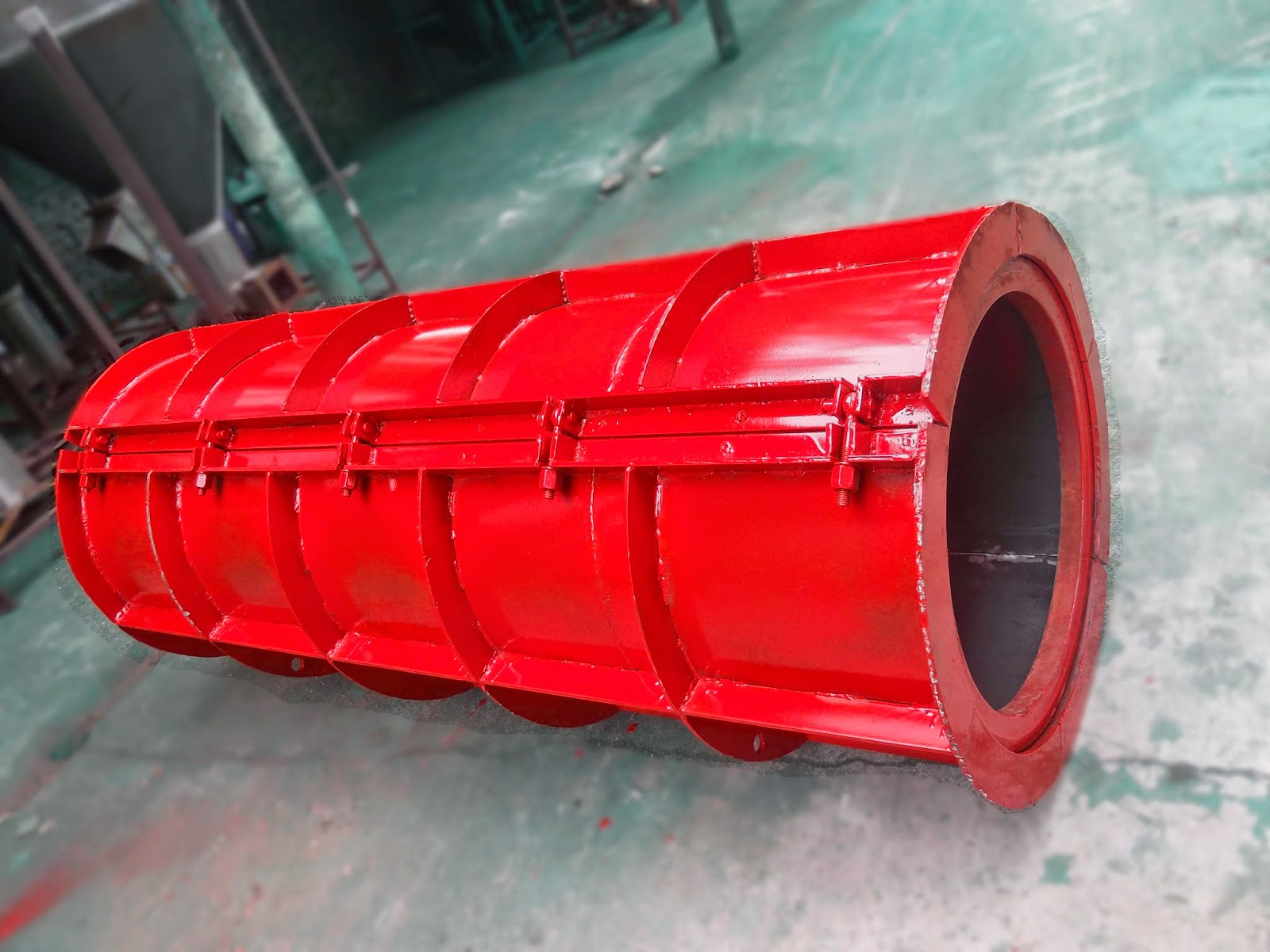

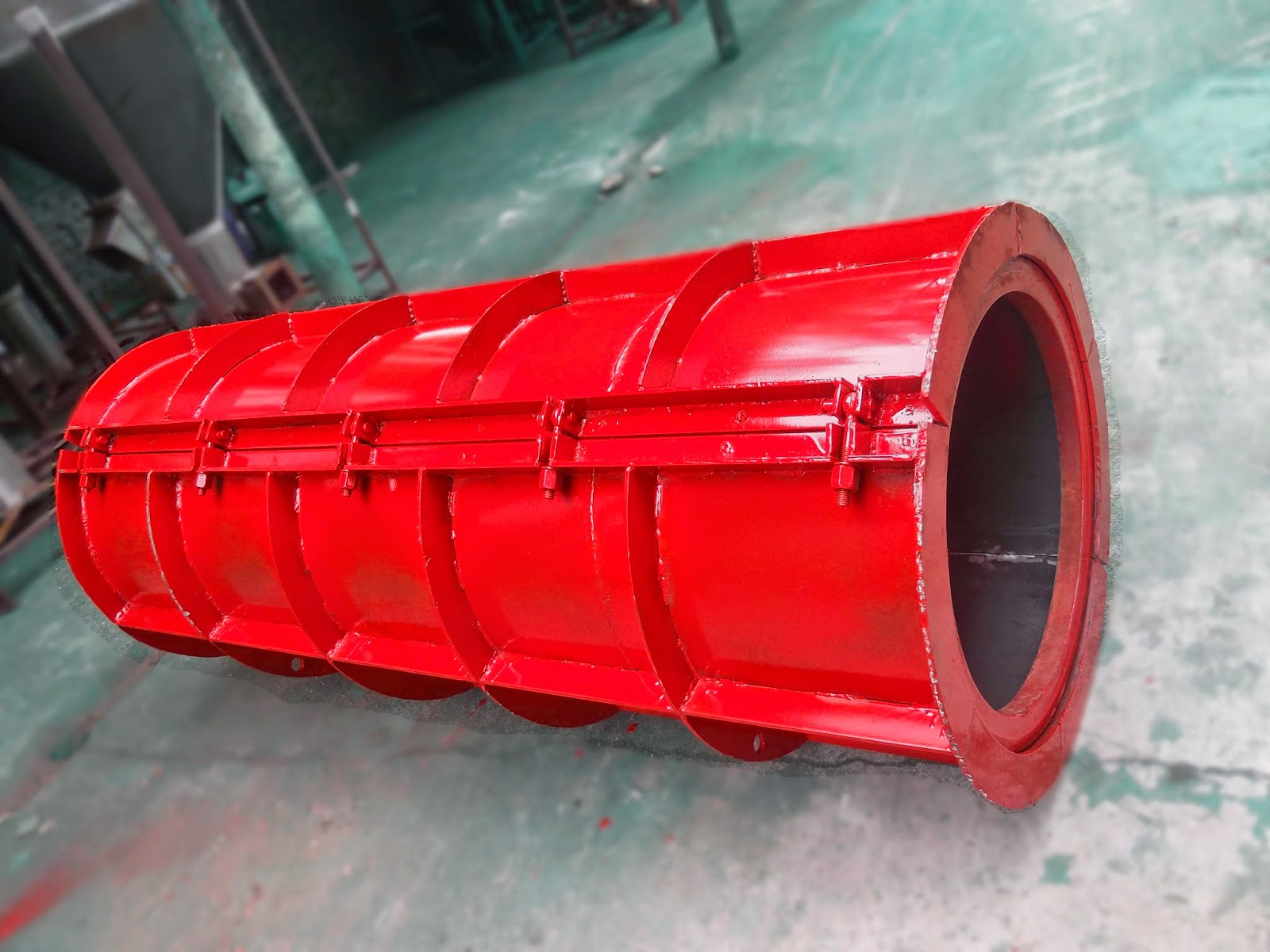

precast concrete pole mould, prestressed concrete pole mould

This Prestressed

Concrete Spun Pole Mould is used for concrete

electrical pole manufacutring. Its mainly manufacture technology is longitudinal

tension by steel wires. Then it can squeeze out the excess water in the concrete

under the centrifugal force. Thus, it can greatly improve the concrete density

and strength.

In

order to form the concrete more quickly to meet the design strength of more than

70%, steam curing can be carried out so as to shorten the mould-releasing

cycle.

Our

factory produces two categories of Pre-stressed concrete

electric pole moulds, DMZ&DMD. The Prestressed Electrical Poles

manufactured by this series equipments comply with national standard of

JC/T364-2001.

Technical Index of Centrifugal type Concrete Pole

Machine

| No. | Item | Unit | Model | ||

| Double-wheel | Three-wheel | ||||

| 1 | Riding wheel thread | MM | 1870 | ||

| 2 | Riding wheel wheelbase | MM | 1500-2800 | ||

| 3 | Riding wheel external diameter | MM | 800-920 | ||

| 4 | Riding wheel width | MM | 100 | ||

| 5 | Angle between wheel center and the center of steel mould | (°) | 75°-110 | ||

| 6 | The Max. length of molding drainage pipe | M | 2-4 | ||

| 7 | The Max. diameter of molding drainage pipe | Plain top/tongue and groove/pipe-jacking | MM | Φ2600 | Φ1800 |

| Bell and spigot | Φ1800 | Φ1800 | |||

| 8 | The motor power | KM | 37-90 | 55-132 | |

| 9 | The range of speed of main drive axle | r/min | 100-500(continuous) | 100-500(continuous | |

precast pipe making machine, hume pipe machine, hume pipe mould

1.Brief introduction of concrete

pipe machine:

CICQ Series concrete

pipe mould has the characters of compact fabric, convenient

maintenance and usage. It is applied to produce reinforcing steel bar waterspout

pipes and other concrete pipe products like culvert pipes with any kinds of

interface (flat, socket and rabbet), which diameter is between 150 to 2000mm,

and the length is between 1000 to 2000mm.

Roller hanging type concrete pipe machine is a kind of machine to produce concrete pipes and Prestress concrete pipe. This machine use the roller to support the pipe mould,and produce roller force to the concrete in the mould. When the roller rotate at a high speed, the concrete in the mould will spread in the inner wall of the pipe mould and form a cement pipe with the centrifugal force.

We can design many kinds of pipe joint, including flush joint(flat mouth type), groove joint, socket and spigot joint(socket and plug mouth type) ect. And all the concrete pipes are widely used in admistrative drainage, agricultural field irrigation, rood culvert and deep water well .

2.

Features of Concrete Pipe Mould

2.1

The adoption of integrated design is reinforced design of leakproof slurry, no

rough edges on which the mouth of pipe joints, easy mold-opening.

2.2

The friction rings in the molds are all made of 45 cast steel.

2.3

The steel plate we use is produced by Laigang which is one of the four major

steel mills, and its abrasion resistance will be guaranteed.

2.4

The carbon-dioxide arc welding is applied into the all welding. The plasma

cutting machine is used for cutting. Welding seam is smooth and nice, and the

cutting seam is very exquisite. All above ensure the mold tough and durable and

extend the service life greatly.

| Type | SZ800x2000mm | SZ1200x2000mm | SZ1650x2000mm | SZ2000x2000mm |

| Pipe Diameter (mm) | 300-800(60m/day) | 800-1200(50) | 1200-1650(40) | 1650-2000(40) |

| Roller Diameter (mm) | 127 | 216 | 273 | 325 |

| Pipe Length (mm) | 2000 | 2000 | 2000 | 2000 |

| Motor Model | YCT225-4B | YCT1250-4B | YCT355-4A | YCT355-4B |

| Motor Power (KW) | 15 | 18.5 | 55 | 75 |

| Rolling Speed (r/m) | 62-618 | 62-61 | 72-727 | 72-727 |

| Machine Dimension (mm) | 4100x2350x1600 | 4100x2350x1850 | 4550x3500x2500 | 4550x3500x2900 |

| Output (pipes/8 hrs) | 30 | 25 | 20 | 20 |

Steel Mould Specification

| Inner Diameter of Top End(mm) | Wheel Distance(mm) | Pole Length(m) |

| Φ100 | 2000 | 6~7 |

| Φ110 | 2000 | 6~7 |

| Φ120 | 2000 | 6~8 |

| Φ130 | 2000 | 6~8 |

| Φ150 | 2000 | 6~10 |

| Φ170 | 2000 | 6~12 |

| Φ190 | 2000 | 7~12 |

| Φ190 | 2000 | 15~18 |

| Φ230 | 2000 | 6~9 |

| Φ310 | 2000 | 6~9 |

| Φ350 | 2000 | 6~9 |

| Φ390 | 2000 | 6~9 |

2015年4月28日星期二

precast concrete machine,hume pipe making machine

1. Overview of Suspension Roller type Concrete Pipe

Machine&Mould

Suspension roller type concrete pipe making machine is a kind of perfect machine and equipment to produce reinforced concrete pipes and Pre-stressed concrete pipe. This machine is capable to make pipes with diameter from 300-2000mm and with length from2-4meters. We can design many kinds of the pipe joint, including flush joint, socket & spigot joint And all the concrete pipes are widely used in administrative drainage, agricultural field irrigation, road culvert and deep water well.

2. Working Principle of Suspension Roller type Concrete Pipe Machine

This machine uses the Roller to support the concrete pipe mould, and produce the roller force to concrete in the mould. When the roller rotate at a high speed, the concrete in the mould will spread in the inner wall of the pipe mould and form a cement pipe with the centrifugal force, and when the mould with the inner concrete pass on the roller, the concrete between the mould and the roller will be compacted solid to form a pipe.

3. Character of Suspension Roller type Concrete Pipe Machine

3.1 Short production Cycle: because of the good effect of the roller to compact the concrete, every pipe just need 3-5 minutes with high speed roller rotation.

3.2 This pipe machine uses the dry cast material, there will no waste cement mud, then it won't pollute the environment.

3.3 During the production, the noise is low, it is about 80-90 DB.

3.4 The concrete pipes are with high pressure load and with high production efficiency.

Technical Data:

Suspension roller type concrete pipe making machine is a kind of perfect machine and equipment to produce reinforced concrete pipes and Pre-stressed concrete pipe. This machine is capable to make pipes with diameter from 300-2000mm and with length from2-4meters. We can design many kinds of the pipe joint, including flush joint, socket & spigot joint And all the concrete pipes are widely used in administrative drainage, agricultural field irrigation, road culvert and deep water well.

2. Working Principle of Suspension Roller type Concrete Pipe Machine

This machine uses the Roller to support the concrete pipe mould, and produce the roller force to concrete in the mould. When the roller rotate at a high speed, the concrete in the mould will spread in the inner wall of the pipe mould and form a cement pipe with the centrifugal force, and when the mould with the inner concrete pass on the roller, the concrete between the mould and the roller will be compacted solid to form a pipe.

3. Character of Suspension Roller type Concrete Pipe Machine

3.1 Short production Cycle: because of the good effect of the roller to compact the concrete, every pipe just need 3-5 minutes with high speed roller rotation.

3.2 This pipe machine uses the dry cast material, there will no waste cement mud, then it won't pollute the environment.

3.3 During the production, the noise is low, it is about 80-90 DB.

3.4 The concrete pipes are with high pressure load and with high production efficiency.

|

Diameter mm

|

Wheel distance mm

|

Wheel diameter mm

|

Length m

|

|

300

|

2000

|

600

|

7-12

|

|

400

|

2000

|

630

|

7-14

|

|

500

|

2000

|

730

|

7-15

|

|

550

|

2000

|

780

|

7-15

|

|

600

|

2000

|

830

|

7-15

|

|

800

|

2000

|

1030

|

7-15

|

|

1000

|

2000

|

1230

|

7-15

|

2015年4月20日星期一

new tech is used to concrete pipe mould

what's new in our cement pipe mould?

1 The adoption of integrated design is reinforced design of leak-proof slurry, no rough edges on which the mouth of pipe joints, easy mold-opening.

2 The friction rings in the molds are all made of 45 cast steel.

3 The steel plate we use is produced by Laigang which is one of the four major steel mills, and its abrasion resistance will be guaranteed.

4 The carbon-dioxide arc welding is applied into the all welding. The plasma cutting machine is used for cutting. Welding seam is smooth and nice, and the cutting seam is very exquisite. All above ensure the mold tough and durable and extend the service life greatly.

pipe diameter:300-2000mm

pipe length:2000mm

mouth type:socket mouth, flat mouth ,and rabbet mouth

Technical Parameter of Concrete Pipe Mold

| Model | Normal Inside Diameter (mm) | Normal Inside Diameter (mm) | Flange Distance Beween Wheel (mm) | Wheel Tread Diameter (mm) | Nornal Length (mm) |

| GMZ103 | Ф100 | Ф150 | 2370 | Ф600 | 3080 |

| GMZ153 | Ф150 | Ф200 | 2370 | Ф670 | 3080 |

| GMZ203 | Ф200 | Ф260 | 2370 | Ф710 | 3080 |

| GMZ253 | Ф250 | Ф320 | 2370 | Ф970 | 3080 |

| GMZ304 | Ф300 | Ф380 | 3120 | Ф970 | 4080 |

| GMZ354 | Ф350 | Ф440 | 3120 | Ф970 | 4080 |

| GMZ404 | Ф400 | Ф490 | 3120 | Ф970 | 4107 |

| GMZ504 | Ф500 | Ф610 | 3120 | Ф1220 | 4107 |

| GMZ604 | Ф600 | Ф720 | 3120 | Ф1220 | 4117 |

| GMZ804 | Ф800 | Ф960 | 3120 | Ф1640 | 4140 |

Our main construction products are as follows:

Cement pipe manufacturing machines in roller hanging type, centrifugal type and vertically compressing type,Concrete pipe mould,Cement pipe mould,Concrete electric pole machine,Concrete feeding machine

Our own machinery factory lies in Qingzhou City,which is the machinery centre of Shandong Province. With excellent products and services, we can make our business easier and more efficient

technique secrets for the cement pole making machine

Broadly speaking, any confidential business information which provides an enterprise a

competitive edge may be considered a trade secret. Trade secrets encompass manufacturing

or industrial secrets and commercial secrets.

As for our products, there do hide some secrets,which will kill me if i told to my

competitors. if you want to know, then contact me secretly.(rebecca@sdcicq.com)

This concrete pole making machine consist of 7 sets of centrifugal machine&30kw frequent c

binet,electric cabinet, centrifugal machine wheel adopt killed steel,same to train wheel raw ma

terial, has strong wear resisance.Steel mold running wheel and centrifugal machine have perf

ctly fitting solid degree Base is adopted

ox structure,the whole machine is equipped with automatic control device, to realize low spee

d,medium speed,high-speed timing control feature.

Technical Index of Centrifugal type Concrete Pole Machine

| No. | Item | Unit | Model | ||

| Double-wheel | Three-wheel | ||||

| 1 | Riding wheel thread | MM | 1870 | ||

| 2 | Riding wheel wheelbase | MM | 1500-2800 | ||

| 3 | Riding wheel external diameter | MM | 800-920 | ||

| 4 | Riding wheel width | MM | 100 | ||

| 5 | Angle between wheel center and the center of steel mould | (°) | 75°-110 | ||

| 6 | The Max. length of molding drainage pipe | M | 2-4 | ||

| 7 | The Max. diameter of molding drainage pipe | Plain top/tongue and groove/pipe-jacking | MM | Φ2600 | Φ1800 |

| Bell and spigot | Φ1800 | Φ1800 | |||

| 8 | The motor power | KM | 37-90 | 55-132 | |

| 9 | The range of speed of main drive axle | r/min | 100-500(continuous) | 100-500(continuous | |

2015年4月17日星期五

two different ways to produce concrete pipe,cement culvert pipe

centrifugally spun concrete pipe system

This technique adopt wet concrete, the pipe body structure has various layers when formed,thus it influence the concrete load resistance. Concrete is usually C30 ,can also do C40. But the pipe nozzle rigidity is lower than the body, not good to be a jacking pipe. During the forming process, concrete pipe mould spun quickly on the centrifugal machine,so does the steel wire cage. These tmay lead to two situation of short life span of the concrete pipe.

1.Steel wire cage has unfasten welding point, result in the steel wire shift or missing,make the pipe locally without steel wire.

2.Wire cage is hardly set in the middle ,Reinforcing mesh is eccentric,namely wire cage protection layer is not even. What’s more, this technique requires large quantity mould to ganrantee the the production, with the mould size deviation and frequent de-molding operation, steel moulds transformation easily occur. Thus lead to Pipe roundness, the perpendicularity of the nozzle, the size of the pipe diameter size and length,which has a bad influence to project quality. The pipeline leakage will cause surface subsidence, can pollute on either side of the soil and groundwater.

roller suspension concrete pipe system

Adopt harsh concrete, pipe structure is even, has great load resistance capacity. We adopt c30 and c40 concrete as raw material. Lower noise than centrifugal technique when pipe forming, clean environment than centrifugal technique. The short coming is, it requires more higher wall

thickness when produce small nozzle pipe to reach the anti-leakage requirement.

2015年4月14日星期二

how to arrange your budget while building utility pole factory?

As a sales, everyday, different clients inquiry from all over the world.

this thing like a doctor receive different patients everyday.

patients wait, but clients come and go(if they cannot hear good suggestions from us.) so it requires us to provide different solution for different clients!

after certain accumulation in utility pole machine market, we get the experience for providing the clients with best factory design, deal with the budget in a rational way.

for Russian and South Asian clients, we suggest advanced,automatic line to make them happy. donnot need to feel painful when you have to invest marge money, it brings you high production and longer machine life span in the future!

for African clients, we have simple and cost effective line.to take full advantage of the lower local labor cost, I can foresee a large amount of fortune for concrete pole in African market.

utility pole career must be a great feat worth us to press on!

this thing like a doctor receive different patients everyday.

patients wait, but clients come and go(if they cannot hear good suggestions from us.) so it requires us to provide different solution for different clients!

after certain accumulation in utility pole machine market, we get the experience for providing the clients with best factory design, deal with the budget in a rational way.

for Russian and South Asian clients, we suggest advanced,automatic line to make them happy. donnot need to feel painful when you have to invest marge money, it brings you high production and longer machine life span in the future!

for African clients, we have simple and cost effective line.to take full advantage of the lower local labor cost, I can foresee a large amount of fortune for concrete pole in African market.

utility pole career must be a great feat worth us to press on!

订阅:

评论 (Atom)